The feed transmission system of the ball valve assembly machine is usually operated by a servo feed system. The function of the servo feed system is to control the movement of the executive parts after amplification according to the command message from the numerical control system, not only to control the speed of the feed movement, but also to precisely control the moving position and trajectory of the tool relative to the workpiece. A typical closed-loop control feed system of ball valve assembly machine is usually composed of several parts, such as position comparison, amplification components, drive units, mechanical feed transmission mechanisms and detection feedback components. Among them, the mechanical feed transmission mechanism of the ball valve assembly machine refers to the whole mechanical transmission chain that changes the rotating motion of the servo motor into the linear feed motion of the table and the tool rest, mainly including the deceleration device, the screw nut pair, the guide parts and their supporting parts. The feed mechanism of ball valve assembly machine is an important link in the servo system. In addition to high positioning accuracy, it should also have good dynamic response characteristics, and the response of the system tracking instruction signal should be fast and the stability should be better.

In order to ensure the transmission accuracy, system stability and dynamic response characteristics of the ball valve assembly machine feed system, the requirements of the feed mechanism are put forward such as no clearance, low friction, low inertia, high stiffness, high resonance rate and adaptive damping ratio. In order to meet these requirements, the following measures are mainly adopted:

Try to use low friction transmission, such as the use of static guide, rolling guide and ball screw, etc., to reduce friction.

Choose the best transmission ratio to improve the resolution of the machine tool, make the workbench as large as possible to accelerate, has reached the tracking instructions, and the moment of inertia of the food system converted to the drive shaft is as small as possible.

Shorten the transmission chain and improve the stiffness of the transmission system by pretightening, such as using the motor to drive the screw directly, applying the preloaded rolling guide rail and rolling screw pair, the screw support is designed to be fixed at both ends, and can be pre-stretched structure and other methods to improve the stiffness of the transmission system.

As far as possible to eliminate the transmission gap, reduce the reverse dead zone error, such as the use of the linkage shaft to eliminate the gap, the use of the transmission pair to eliminate the gap measures.

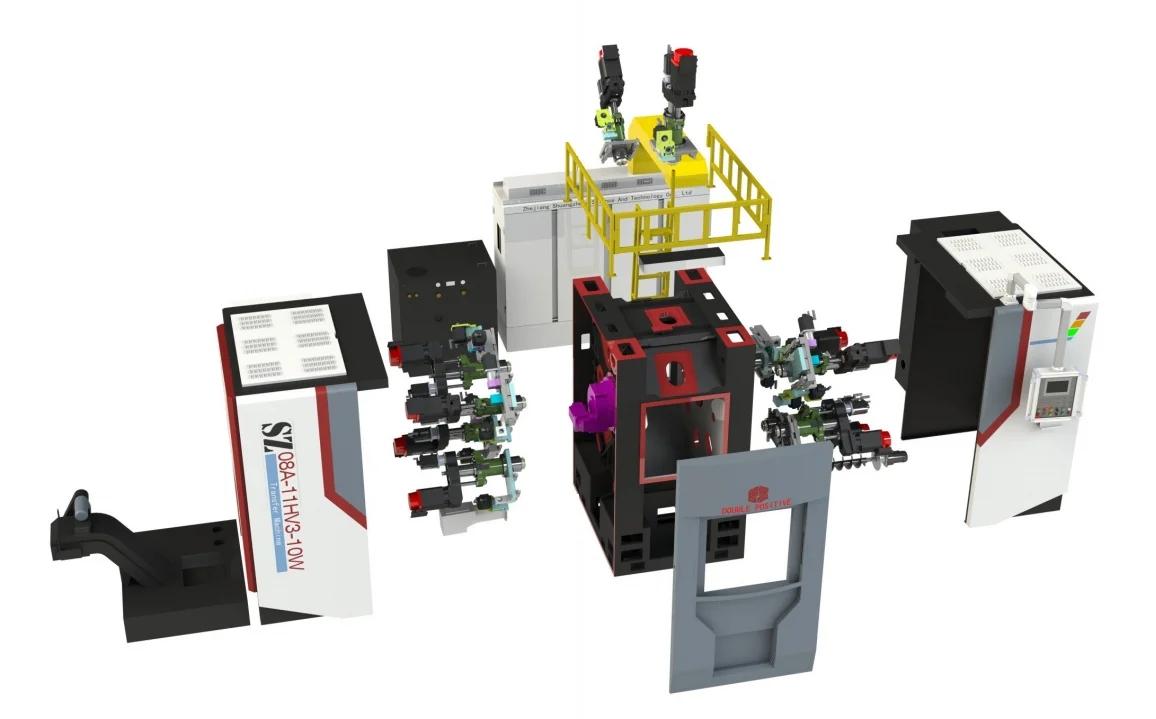

ball valve assembly machine https://www.zjshuangzheng.com/Rotary-Table-Intelligent-Assembly-Machine.html